You are here

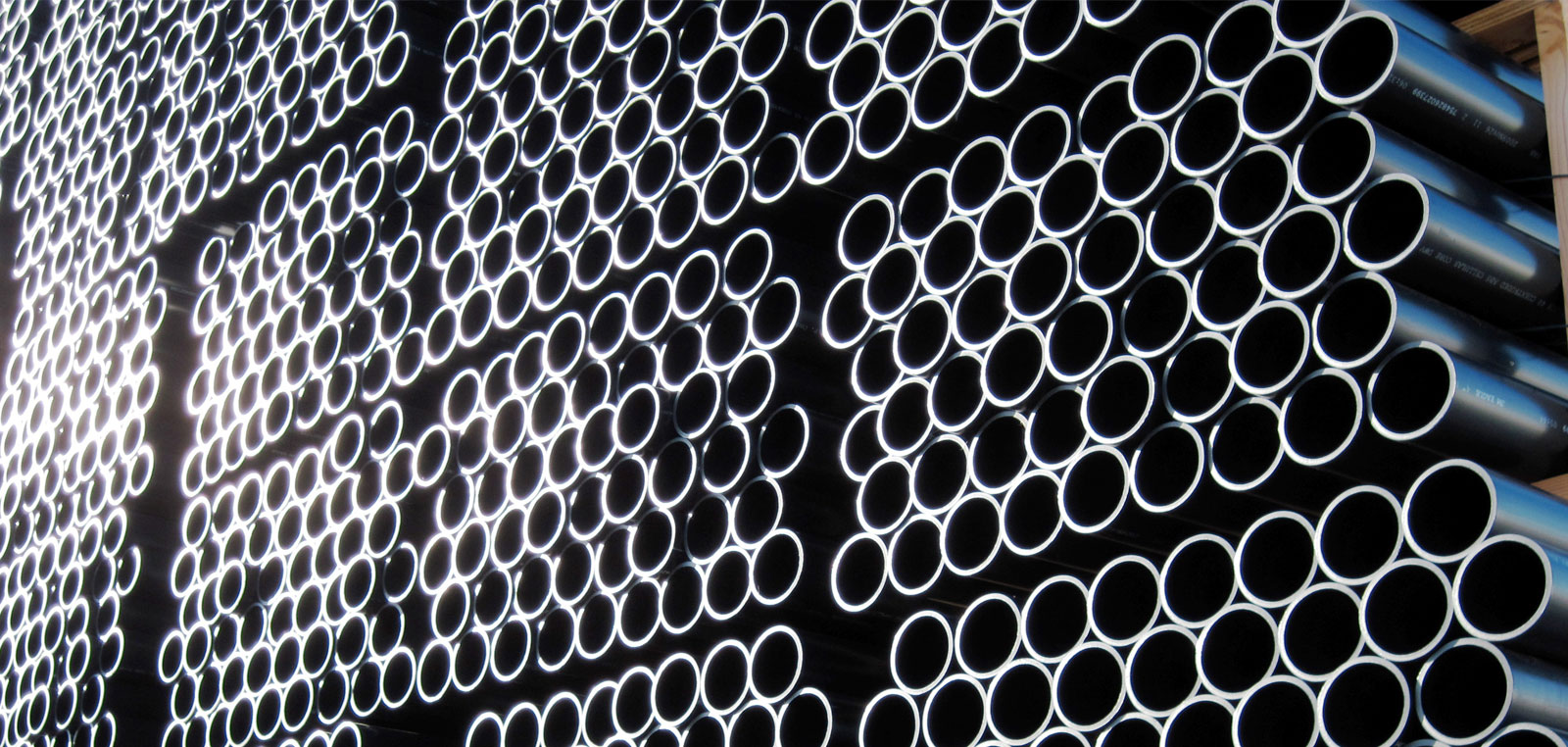

Solvent Weld ABS

JM Eagle Solvent Weld Acrylonitrile Butadiene Styrene pipes are suitable for use in commercial, residential and industrial installations for sanitary drain, waste and vent applications.

JM Eagle Solvent Weld ABS pipe is lightweight, cost-effective and longlasting.

- It can be field-cut with a power saw or ordinary handsaw without the use of expensive or complicated machinery.

- Easy to load, transport and handle, installers prefer it because it goes into the ground quickly, saving installation costs.

- It maintains performance against tuberculation, corrosion and external galvanic soil conditions without lining wrapping, coating or cathodic protection.

- It keeps its smooth interior over long years of service with virtually no loss in carrying capacity

- It can be connected directly to most plumbing and IPS fixtures without complicated procedures or adapters, as well as into CIOD fittings with adapters and/or transition gaskets.

- A cured joint of JM Eagle Solvent Weld ABS pipe offers a zero-leak connection that is structurally sound.

Meets ASTM F628 or ASTM 2661.

JM Eagle Solvent Weld Acrylonitrile Butadiene Styrene pipes are suitable for use in commercial, residential and industrial installations for sanitary drain, waste and vent applications.

JM Eagle’s wide line of Solvent Weld ABS pipe is available in 5-, 10- and 20-foot lengths in diameters of 1 ½ to 6 inches. ABS pipes are available in both solid and cellular core. Solvent Weld joints are designed to provide a rigid (or restrained) joint connection